Technology of pigging lengthily uncleaned pipelines

Key cleaning concept – avoiding the deposit-plugging of the crude oil pipeline. Research the degree of deposit buildup on the pipeline wall along the entire length and assemble temporary cleaning pig launcher and catcher stations.

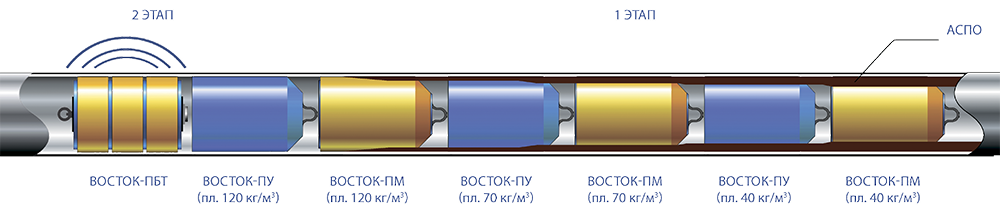

1 stage – recurrent cleaning using soft (S) and reinforced (R) foam cleaning pigs.

During the 1st run, it is necessary to launch the “VOSTOK-PM” cleaning pig of diameter smaller than that of the cleaned pipe-line, with density= 30-40 kg/m?, and track the pig’s running using the acoustic device “Sensor”. Later on, the diameter and the densi-ty of foam cleaning pigs each time should be adjusted according to the results of previous pig run, i.e. after removal of the pig from the pipeline the information on its condition (degree and kind of dam-age) should be analyzed, as well as the type, quantity and com-pound of foreign objects and deposits extracted from the pipeline.

Cleaning of the crude oil pipeline with foam cleaning pigs should be conducted until the degree of removed pigs’ changes (damages) is minimal.

2 stage – recurrent cleaning using “VOSTOK-PBT” “Pun-cheon”-type foam cleaning pig, installed on transmitter’s body.

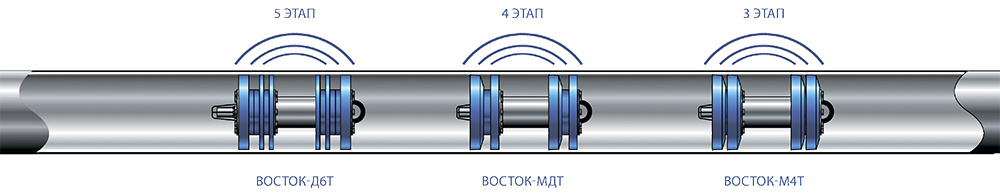

3-5 stage – cleaning using “VOSTOK-M4T”, “VOSTOK-MDT” and “VOSTOK-D6T” cleaning pigs with conical and straight polyurethane cups and disks (conical cups are re-placed with straight disks between the runs).

6 stage – check run of the cleaning pig with polyurethane disks and brushing unit.

At all stages of cleaning the crude oil pipeline, the pigs should be tracked using the acoustic mole “VOSTOK-AL” and low-frequency mole “VOSTOK-NL”.